CAPIQ

CAPIQ

Capiq Engineering is a world-class engineering organization, primarily engaged in custom manufacturing of precision machined components and assemblies.

We generally deal with relatively small metallic parts and assemblies weighing a few grams to around 100 kgs. Capiq was founded in 1991, by engineers having long experience in, reputed organizations in U.S.A. and large limited Companies in India. The basic strength of Capiq is in comprehensive capabilities in the field of manufacturing, design recommendation for manufacturability, Quality control and business management.

The main charter of Capiq is to meet customers' requirement of quality and schedules. This is made possible due to promoters’ familiarity in using statistical process control. Past experience of promoters in managing time bound projects helps in meeting schedules. Combining these factors along with a foundation of ethical business practices has enabled Capiq to establish credibility as a reliable business partner.

Capiq by design has decided to serve world leaders in their respective field by meeting their quest for impeccablequality at outstanding value. If we can satisfy them, then Capiq will not only survive but thrive

Capiq’s vision is to be accomplished through ethical practices. This is also to be achieved by taking along the employees and vendors as a team to the necessary higher level of performance to benefit all.

Capiq has a track record of successfully exporting approximately 95% of its total production to quality conscious, ISO 9000 American and European customers.

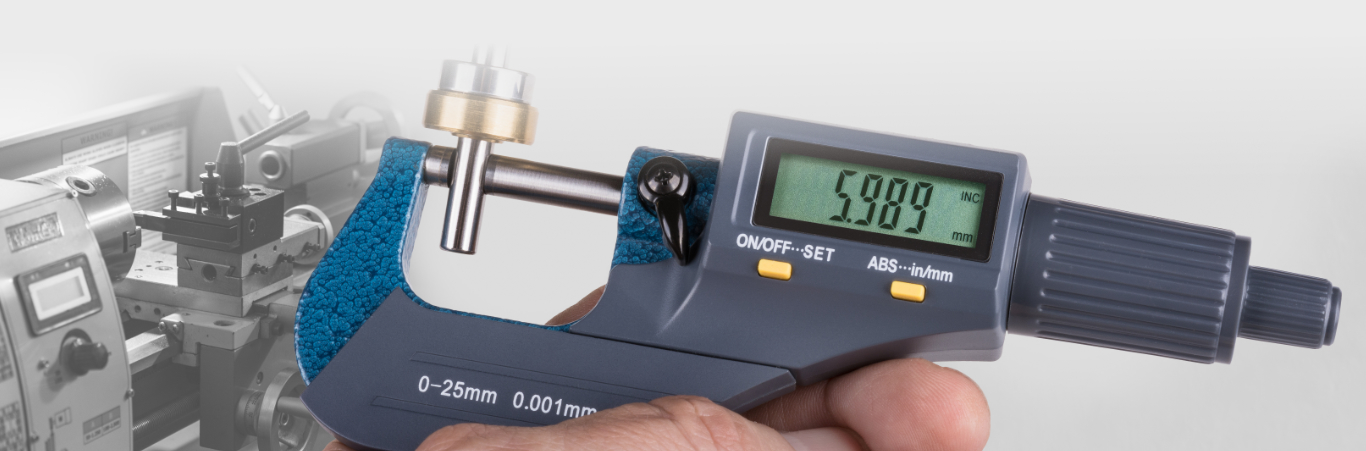

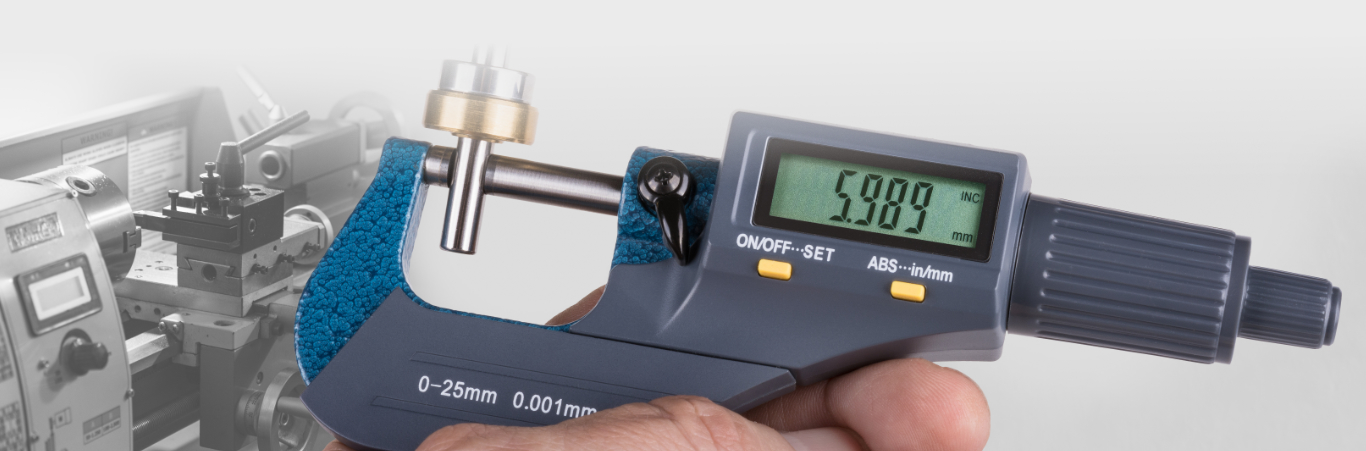

We have also been catering to Multinational and Export oriented units in India. The parts made for the above customers are typically having tolerances down to 0.001 to 0.015 mm range. They are made from Hardened OHNS(W), Aluminum alloys, EN1A leaded steel, A2 Tool Steel, various grades of SS, exotic alloys, UHMW plastic, etc. The quantities are from 500 to 20,000 pieces a month. These parts are required for hydraulic/pneumatic cylinder assemblies, assemblies of high precision machines for Semiconductor industry, assemblies for Medical equipments, implants, Robotics, winding fixtures for voice coils of disc drives, etc.

Apart from machining of precision components, we are capable of undertaking jobs involving Product Development, Assembly and testing. Sub-assemblies presently manufactured at Capiq go into special purpose machines, hydraulic/pneumatic automation systems, textile capital goods, semi-conductor capital equipments and high-end medical equipments.

Personnel

Equipment

Manufacturing systems and Quality Assurance

Vendor Development

Apart from the promoters, who have extensive technical and management experience, the Quality Assurance and Manufacturing departments are staffed by technically competent personnel.

The operations are complimented by other adequately staffed departments such as Vendor Development, Materials Management, Marketing, Finance and Administration. Capiq has very well defined systems in place for procuring the raw material, incoming inspection, in-process inspection, handling of deviations, finished goods inspection and testing of assemblies. Comprehensive records are kept to maintain traceability from raw material to finished goods stage and performance of the assemblies. Capiq also has comprehensive systems in place for production planning and control. These help us in meeting requirements of our customers as committed.

Capiq is able to leverage the in-house capability, with additional capacities available at the vendor’s place. This enables Capiq to be more responsive to fluctuation in demand from regular customers. All the Capiq QA standards are implemented at the vendor’s place.

A well balanced combination of infrastructure enables Capiq to be a truly world-class engineering organization.