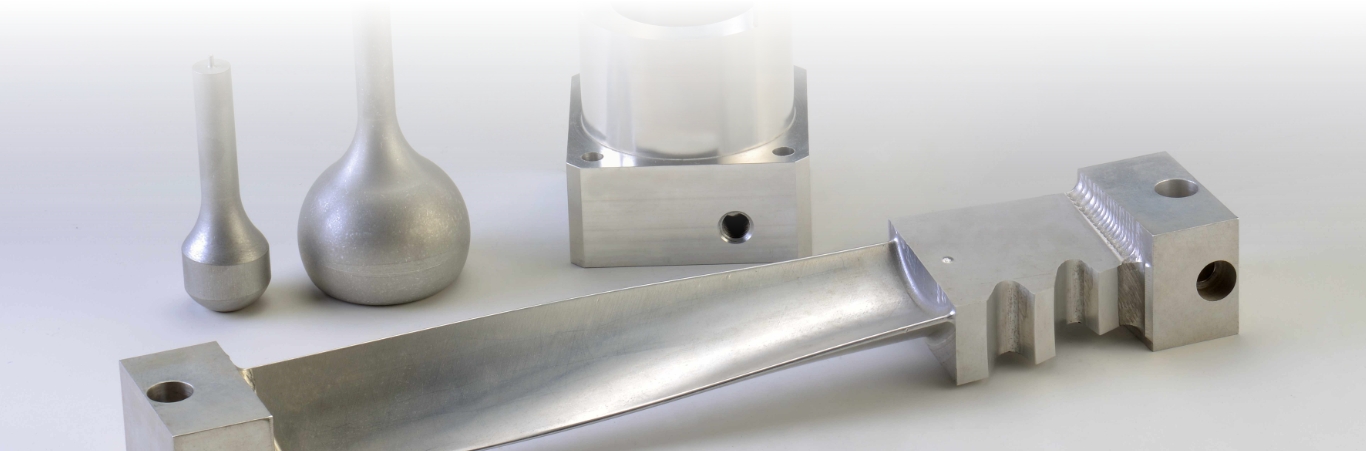

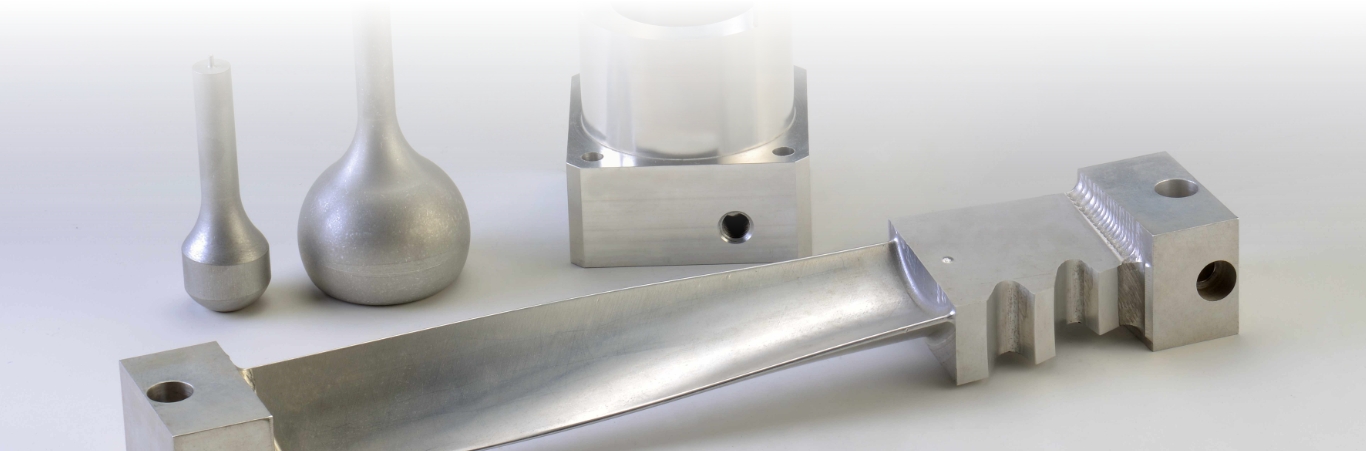

DFMA Suggestions for Clients

- DFMA helps to reduce cost by selection of alternative design and material

- Small changes in parts using DFMA provides higher saving and reduce rejection

- Suggestions from client are accepted and we make sure to create flexibility in manufacturing during the transition stage

- DFMA changes suggested as per the functionality of part

- Discussion with client’s design team as their previous experience on the part

- For assembly parts, DFMA includes A-B-C analysis and calculations to arrive to an optimum manufacturing and assembling cost

- Dedicated team of engineers at Capiq with excellent knowledge and sound experience in design and manufacturing